VeFo-Flex Sprint

Price per m² from: €21.00 Price per m²: €18.90 Price per m²: €21.00 incl. VAT plus shipping costs. Item no. 643201

Delivery time approx. 3-6 days

CNC cutting accurate to the millimetre

free assembly tool

Start WhatsApp chat

VeFo-Flex Sprint textile film

Our VeFo-Flex Sprint films are suitable for high-quality textile finishing, using transfer presses and irons. These newly developed flex films are polyurethane films with a

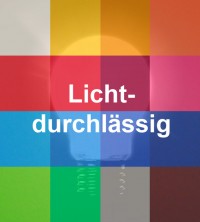

hot-melt adhesive that can be processed quickly and without damaging the material. These films have a thickness of approx. 90µm and are excellently suited for your own design or upgrading of textiles made of cotton, polyester, acrylic, their blended fabrics and also nylon. Our VeFoFlex films are available in many different colours and can be processed on top of each other without any problems, with the exception of metallic and neon colours.

All VeFo-Flex films are suitable for processing on all standard cutting and table plotters. We recommend the use of a standard cutter (45°). All materials used in VeFo-Flex films are ecologically safe and free of PVC, plasticisers and heavy metals.

These films are certified according toOekoTex® Standard 100 product class 1.

These films are washable up to 60°C, suitable for tumble dryers (commercially available tumble dryers up to max. 100°C) and resistant to dry cleaning. The soft, rubber-elastic transfer film has a pleasant textile feel and is very comfortable to wear. It also has excellent opacity.

Please note that the colour reproduction can only serve as a non-binding orientation.

Manufacturer's guarantee

Only if the specified temperature and pressure conditions of the hot transfer are adhered to, a secure and permanent anchorage of the flex film is guaranteed.

We recommend carrying out an application test on original materials. Due to the many influences resulting from the manufacture and transfer of the transfer film,

the nature of the materials as well as the washing and cleaning conditions, product liability can only apply to unprocessed materials.

| Technical data | |

|---|---|

| Transfer film | Polyurethane, cast |

| Adhesive | Polyurethane hot melt adhesive |

| Thickness in (mm) | 0,095 +/- 5 % |

| Liner | PET film, self-adhesive |

| Transfer conditions Cotton and blended fabric | |

|---|---|

| Temperature and press time | 130 °C, 5 sec. / 150 °C, 4 sec. / 160 °C, 3 sec. |

| Pressure | 2,5 - 3,0 bar [medium pressure] |

|

For very structured cotton and blended fabrics, the pressing time has to be adjusted. |

| Transfer conditions Nylon fabric | |

|---|---|

| Temperature and pressing time | 150°C 5 sec. prepress 5 sec. press on nylon Remove PET liner, cover transfer with silicone paper, press for further 10 sec. |

| Pressure | 2,0 bar [low pressure] |

| Washing resistance | |

|---|---|

|

60 °C tumble dryer suitable (commercially available tumble dryers up to max. 100°C) and dry-clean resistant. Turn textile inside out before washing. |

General questions

Can I get a free foil sample?

Of course, please click on this link to access the corresponding order form. You are welcome to add to the list of items if you wish. There are no costs for you!

Will you also cut the film for me?

We cut each film to the exact millimetre according to the dimensions you enter. The cutting is free of charge. You can find detailed instructions on how to measure your panes here.

Alternatively, you can also cut your film by hand with a cutter knife. However, this requires a little manual skill, so you are usually better off using our free service.

Can you also cut a round blank or other geometry?

In general, almost all 2D shapes can be produced. Many geometries (e.g. triangles, trapezoids, circles) can be ordered directly via the online shop. To do so, please click on the orange rectangle to the right of the article image. You can then choose between many different shapes.

For shapes that are not specified, please send us a small sketch (photo) in which you specify the side lengths, radii or angles. Please contact us for this purpose.

Does the film also adhere to surfaces other than glass?

The window film adheres to all surfaces that are approximately as smooth as glass. When applying the film to plastic, please bear in mind that the adhesive may bond with the plastic, making it impossible to remove the film cleanly later.

How can I clean my window pane with the film in place?

You can keep your window pane clean as usual. The film should not be rubbed with sharp-edged objects (e.g. a brush).

You can find more information in our guide General care instructions for window films.

Can the film be removed without leaving any residue?

All window films can be removed without leaving any residue and without damaging the glass surface!

Below you will find detailed instructions on how to remove old window films.

Can you also print on films?

Unfortunately, we do not currently offer foil printing and do not have any partner companies with whom we can realise foil printing.

Expert adviser Thomas de Jong - Customer support

» Open questions about one of our articles? I'll be happy to answer them for you! «

Rate this item objectively and share your buying experience with other visitors.

As a thank you, we will reward you with a shopping voucher* of up to 10€ for your next purchase.

*Voucher valid for 1 year, redeemable from 30€ value of goods (5€ voucher) or 50€ value of goods (10€ voucher), max. 1 voucher per order, not combinable.

The voucher will then be sent to you by email.

You will receive an email from us after the rating has been activated in which you will find the shopping voucher.

New reviews are activated by us every working day.

The company Velken-Folientechnik GmbH accepts this assignment and ensures the necessary data protection.